Product data management (PDM) plays a crucial role in modern business environments. As companies strive for efficiency and innovation, effectively managing product data has become essential. This includes not only technical specifications and version control but also seamless collaboration among cross-functional teams. Understanding PDM can elevate a company’s operations and foster a competitive edge in the market.

What is product data management (PDM)?

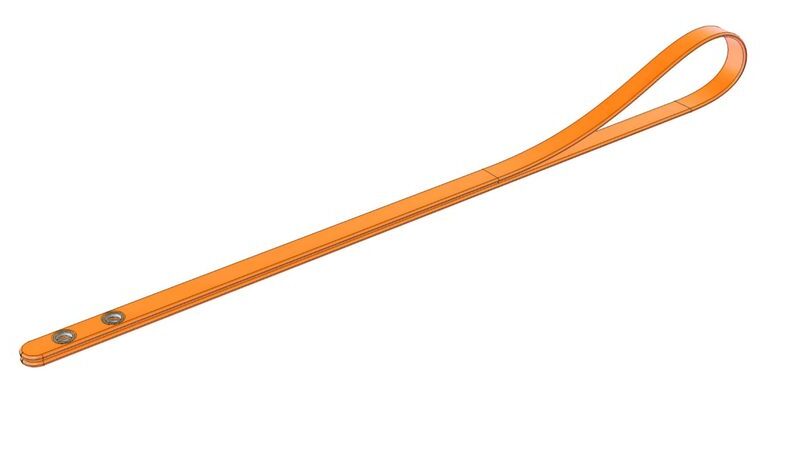

Product data management (PDM) refers to the processes and systems that organizations implement to collect, manage, and distribute electronic data related to their products. This data can encompass a variety of information, from engineering models and CAD drawings to technical specifications and documentation. By utilizing PDM, companies can streamline workflows and enhance collaboration across different departments.

Key components of product data management

The effectiveness of PDM hinges on its key components, which work together to maintain an organized structure for product data.

- Centralized database and software applications: A centralized database is vital in enabling easy access to product information. Various software applications support this database, enhancing data management and collaboration.

- Technical specifications and documentation: PDM manages diverse technical documents, ensuring that bills of materials, design drawings, and specification sheets are systematically organized.

- Features enhancing PDM functions: Key features such as version control and security protocols safeguard the integrity of data while boosting operational efficiency.

Who uses product data management?

Understanding who leverages PDM can offer insights into its significance across various sectors.

Primary users: engineers

Engineers play a pivotal role in managing product data, as they are primarily responsible for creating and updating product designs and specifications. They rely heavily on PDM systems to ensure accurate and timely access to essential information.

Cross-functional users in PDM

In addition to engineers, several other professionals benefit from PDM systems. Operations managers utilize PDM to optimize production schedules, while salespeople depend on accurate product data to provide customers with reliable information and support sales efforts.

Product data management vs. product lifecycle management

While PDM and Product Lifecycle Management (PLM) both focus on managing product information, their scopes and applications differ.

The relationship between PDM and PLM

PDM serves as a foundational element for PLM, which encompasses a broader strategy for managing products throughout their lifecycle, from ideation to end-of-life.

PDM’s origin and evolution

Originating in the CAD industry, PDM has evolved to become integrated within more extensive enterprise applications, allowing for enhanced product data management capabilities within various organizational contexts.

Related topics for further exploration in PDM

Examining related topics can enrich understanding and highlight the interconnected nature of product data management.

- Interconnection with product information management: PDM plays a crucial role in supporting holistic product information management systems, improving data consistency and accessibility.

- Impact of IoT on PDM and PLM: The rise of IoT technologies has significantly influenced the evolution of PDM and PLM platforms, allowing real-time data integration and monitoring.

- Technological advances: edge computing and PDM: New trends at the intersection of edge computing, IoT, and product design are reshaping how data is managed and utilized in PDM.

- Adopting a circular economy model: Embracing circular economy principles within product management fosters operational resilience and promotes sustainable practices.

- Understanding enterprise management systems: Clarifying the distinctions between PDM, Enterprise Asset Management (EAM), and Computerized Maintenance Management Systems (CMMS) can help in selecting appropriate solutions for businesses.

- Digital twins and product-as-a-service: Concepts like digital twins are transforming traditional product management approaches, offering innovative ways to enhance PDM.

- End-of-life (EOL) processes in PDM: Understanding EOL processes helps differentiate PDM from PLM software solutions, focusing on managing product data through its lifecycle.